In the rapidly evolving power sector, transformer oil testers in India have emerged as indispensable instruments for maintaining the proper functionality and performance of transformers. These devices are vital for preventing transformer failures, which may have serious implications for the power grid stability and reliability.

Transformer oil, a key component in the operation of transformers, serves as an insulator and helps in cooling the system. However, over time, the oil may degrade and become contaminated, leading to reduced efficiency and potential failures. As India continues to expand its power infrastructure to meet the growing industrial and residential demands, the role of transformer oil testers becomes increasingly crucial. Regular testing and analysis of transformer oil are essential for ensuring the longevity and optimal performance of transformers.

The Indian market for transformer oil testers is characterized by a diverse range of products tailored to different aspects of transformer oil testing. These include moisture testers, dielectric strength testers, gas analyzers, and more. Each type of testers serves a specific purpose and facilitates the comprehensive evaluation of transformer oil condition. The application of these testers not only ensures the efficient operation of transformers, but also helps in preventive maintenance, thereby reducing the likelihood of costly downtimes and extending the equipment lifespan.

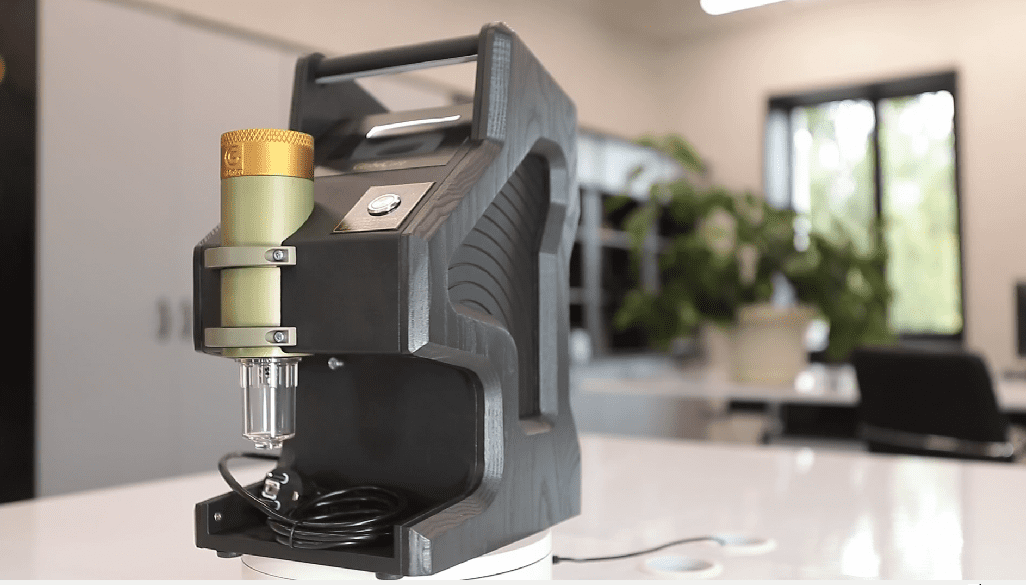

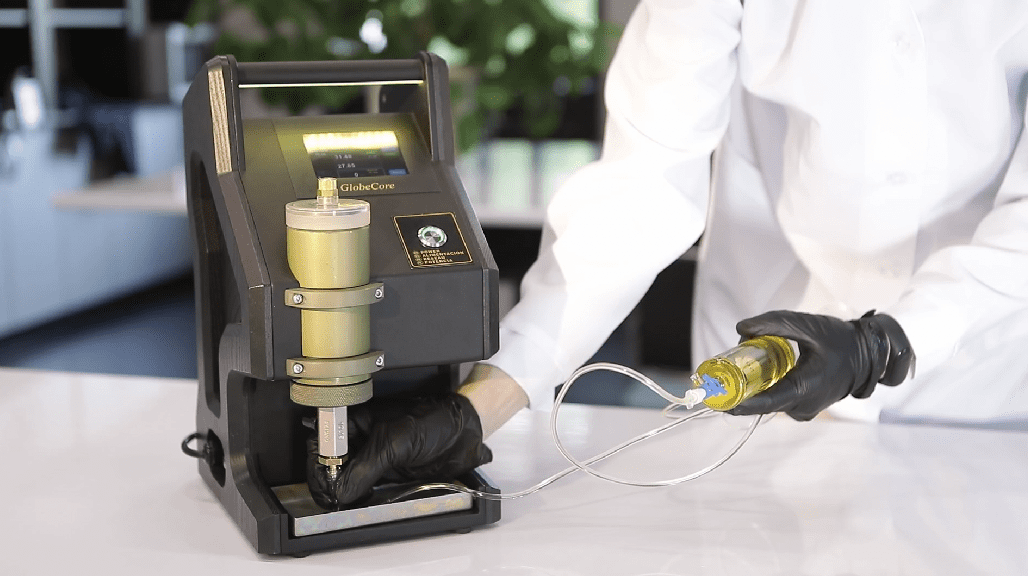

Oil moisture testers (TOR-1)

The TOR-1 oil moisture testers represent a significant segment of transformer oil testing in India. Moisture in transformer oil is a major concern, as it can lead to a host of problems, including reduced insulation resistance, increased risk of dielectric breakdown, and accelerated aging of oil. The presence of moisture may be attributed to several factors, such as leaks, condensation, or poor handling practices.

The TOR-1 testers employ the technologies that accurately measure the moisture content of transformer oil. By providing the accurate and reliable moisture readings, the TOR-1 testers enable maintenance teams to take timely and appropriate corrective actions. These actions may include oil dehydration, repair of leaks, or oil change when necessary.

The importance of moisture testing is particularly pronounced in India’s tropical climate, where high humidity and temperature fluctuations increase the risk of moisture ingress into transformer systems.

Hydrogen and moisture testers (TOR-2)

The TOR-2 testers represent a notable technological advancement in the field of transformer oil testing within India. These testers are designed to simultaneously measure two parameters of transformer oil: moisture content and hydrogen concentration. The presence of hydrogen in transformer oil clearly indicates various transformer issues, which include partial discharge, arcing, and overtemperature — all of those may lead to catastrophic transformer failures if not detected and addressed in a timely manner.

Recognizing the critical importance of hydrogen analysis, the TOR-2 testers employ advanced measurement technologies. The data they provide are essential for implementing the preventive maintenance strategies, which are invaluable to India’s expanding power sector, where transformer downtime could have extensive and diverse implications for both industrial and residential power supply.

In addition to hydrogen analysis, the TOR-2 testers also accurately measure the moisture content of transformer oil. Moisture and hydrogen often coexist in transformer oil, and the combined analysis of their amounts offers a more comprehensive insight into the transformer state. This dual functionality makes the TOR-2 an invaluable instrument in the toolkit of maintenance teams across India and allows for more informed decision-making, thus enhancing the overall reliability of the power transmission and distribution network.

Tan delta testers (TOR-3)

Tan delta testers (TOR-3) represent another essential class of transformer oil testing equipment widely used in India. The tan delta, or dielectric dissipation factor, is a key parameter that reflects the condition of transformer oil and its insulating properties. As transformer oil ages, it undergoes chemical changes that can compromise its dielectric strength and overall insulating performance. Measuring the tan delta value provides a reliable means of assessing these changes and determining whether the oil remains suitable for continued use.

The TOR-3 testers are specifically designed for this purpose. These portable instruments are highly valued for their accuracy, speed, and ease of use, making them an ideal choice for both field and laboratory testing.

Breakdown voltage testers

The breakdown voltage testers, such as the TOR-80, TOR-80A, and TOR-100 models, are integral components of transformer oil testing systems in India. These testers are designed to measure the dielectric strength of transformer oil, which is a key indicator of the oil’s ability to perform as an insulator and prevent electrical breakdowns.

Dielectric strength is a critical property of transformer oil, as it determines the oil’s ability to withstand electrical stress without losing its insulating properties. Over time, the factors such as contamination, moisture ingress, and oil degradation may considerably reduce dielectric strength. This reduction can compromise insulation, potentially causing transformer failures that lead to costly repairs and prolonged downtime. In a country like India, where the demand for reliable electricity is continually rising, maintaining the optimal condition of transformer oil is not just a technical necessity, but also a vital component of energy security.

The TOR-80, TOR-80A, and TOR-100 transformer oil testers employ internationally recognized testing methods to accurately determine the dielectric strength of transformer oil. These methods comply with global standards including ASTM D877, D1816, and IEC 60156. The testing process involves gradual increase of voltage applied to a sample of transformer oil until a dielectric breakdown occurs. The voltage at breakdown is recorded as dielectric strength of oil. This process is used for identifying the oil samples that no longer meet the required performance standards and may need treatment or change.

One of the key features of these testers is their ease of use and rapid testing capability. They are designed to deliver prompt and accurate results, which is essential for on-site testing and immediate decision-making. This feature is particularly valuable in remote and rural areas of India, where access to laboratory facilities for detailed oil analysis may be limited. Through on-site testing, these instruments considerably reduce the turnaround time for maintenance decisions.

GlobeCore ensures the production of all essential transformer oil testers required for the Indian market. With a range of innovative and reliable testing solutions, these testers enable maintenance teams to effectively detect and prevent transformer failures, optimize the transformer performance, and extend the equipment lifespan. Transformer oil testers in India are not merely instruments, but also integral components in maintaining the efficiency and reliability of the power generation and transmission infrastructure.

Oil Moisture Meter ...

Oil Moisture Meter ... Hydrogen and Moisture ...

Hydrogen and Moisture ... Oil Tan Delta ...

Oil Tan Delta ...