A hydrogen analyzer for transformer oil in India plays a crucial part in sustaining the energy sector. In this country, the demand for accurate and reliable transformer oil testing is on the rise, particularly for hydrogen analysis.

Hydrogen in dielectric liquid serves as a leading indicator of potential faults and early degradation within the transformer insulation system. Thus, the ability to accurately and efficiently measure hydrogen levels in transformer oil is critical for preventing the costly failures and ensuring the longevity of these power grid components.

Significance of a hydrogen analyzer for transformer oil in India

Hydrogen developing in transformer oil is often a byproduct of several underlying issues, such as electrical arcing, overtemperature, or insulation degradation. These conditions lead to the degradation of oil and insulation materials, releasing hydrogen as a primary decomposition product. The presence of hydrogen in transformer oil, therefore, serves as an early warning signal of these detrimental processes. Monitoring the hydrogen levels on a regular basis, transformer operators can take preventive actions to address these issues before they escalate into major failures. In the context of India’s diverse and often challenging operating environments, this capability is particularly valuable, allowing for more effective maintenance scheduling, reducing the downtime, and extending the operational life of transformers.

Disadvantages of determining the hydrogen content of transformer oil by chromatographic analysis

Determining the hydrogen content of transformer oil by chromatographic analysis has long been regarded as the standard practice in the industrial sector. However, the application of this technology has several disadvantages, particularly in the context of India, where remote locations and limited resources may pose additional challenges.

Primary disadvantages:

- Time-Consuming and Cost-Intensive: chromatographic analysis requires extremely precise instruments and highly skilled technical professionals. This considerably increases the time and cost of analysis, which is a critical disadvantage under the present-day conditions requiring rapid response to changes in oil quality.

- Delivery of Samples: conducting a chromatographic analysis necessitates the delivery of oil samples to a laboratory. This may be inconvenient and costly, especially in remote or rural areas of India.

- Complexity and Skill Requirement: the technique requires specialized knowledge and expertise for both operation of equipment and interpretation of results. This requirement may be a serious contraint in regions with limited access to trained personnel.

- Limited On-Site Applicability: chromatographic analysis is not suitable for on-site testing. This limitation may delay decision-making in time-critical situations where immediate analysis is crucial for transformer maintenance.

- Environmental and Safety-Related Concerns: the process often involves handling the hazardous chemicals and solvents, which pose environmental and safety-related risks. These risks increase in the areas where proper disposal facilities and safety protocols are missing.

- Susceptibility to Errors: the accuracy of chromatographic analysis may be affected by various factors, such as sample handling, contamination, and instrument calibration. Inconsistent results may lead to misinterpretations and incorrect maintenance decisions.

- Infrastructure Requirements: the need for specialized laboratory infrastructure makes it a less feasible option for widespread and frequent monitoring across India’s diverse and extensive power grid.

- Scalability Issues: given the vast number of transformers across India, the scalability of chromatographic methods becomes a challenge, particularly in terms of logistics, manpower, and costs.

While chromatographic analysis provides accurate results, its disadvantages associated with time, cost, complexity, and lack of on-site applicability make it less suitable for the dynamic and diverse requirements of the Indian electric power industry. These limitations emphasize the need for more practical, efficient, and accessible solutions like a TOR-2 hydrogen analyzer for transformer oil testing in India.

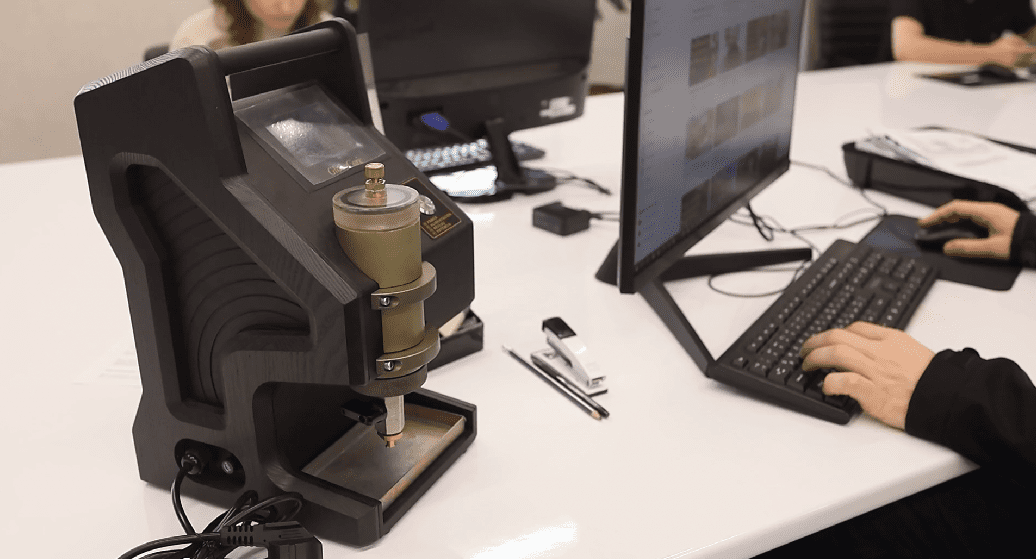

TOR-2 hydrogen analyzer for transformer oil by GlobeCore

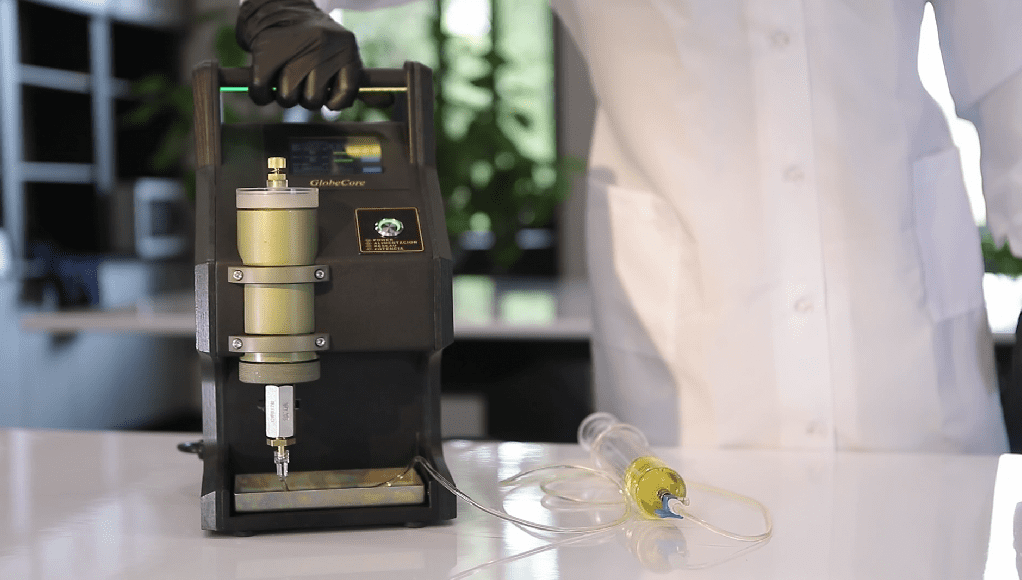

The TOR-2 hydrogen analyzer is developed by GlobeCore as a helpful instrument for transformer oil testing. This analyzer represents a significant technological advancement compared to conventional methods, offering a comprehensive solution to the challenges previously faced in hydrogen analysis. The TOR-2 is designed to provide rapid, accurate, and reliable hydrogen level readings in the field, avoiding the need for complex laboratory procedures. This portability and ease of use make it an ideal choice for widespread application across India’s diverse and expansive electrical infrastructure.

One of the key features of the TOR-2 hydrogen analyzer is its advanced sensor technology. The unit employs a highly sensitive and selective solid-state sensor designed to detect even minute amounts of hydrogen in transformer oil. The direct immersion of this sensor in an oil sample ensures immediate and accurate readings. Additionally, the analyzer is calibrated to account for the varying compositions of transformer oils used in India, which enhances its precision and reliability in different operational environments.

Advantages of TOR-2 hydrogen analyzer

The TOR-2 hydrogen analyzer offers a host of benefits that make it an essential instrument in transformer maintenance. Its design and functionality are specifically optimized to address the unique challenges faced in India. Here are the key advantages:

- Rapid On-Site Testing: the TOR-2 enables rapid and accurate hydrogen level evaluation directly on site, as well as facilitates immediate decision-making and timely interventions.

- User-Friendly Operation: it is designed for ease of use, requires minimum training, which makes it accessible for a wide range of users, including those in remote areas or with limited technical expertise.

- Advanced Sensor Technology: equipped with highly sensitive and selective sensors, the TOR-2 accurately detects even minute amounts of hydrogen in transformer oil.

- Cost-Effective Solution: its low operational costs along with elimination of the need for consumables and regular recalibrations, make it a financially viable option.

- Durability and Reliability: built to withstand a variety of environmental conditions prevalent in India, the analyzer ensures consistent performance in both humid and dry regions.

- Portability: the compact design of TOR-2 makes it easy to transport and use in various locations, from urban centers to remote rural areas.

- Enhanced Safety Features: the design prioritizes operator safety, reducing the risk associated with handling and analyzing of transformer oil.

- Environmental Friendliness: the operation of TOR-2 does not involve hazardous chemicals or solvents, making it a more environmentally sustainable option.

- Scalability for Widespread Use: its ease of use and cost-effectiveness make the TOR-2 suitable for deployment across a large number of sites to facilitate widespread monitoring within the power grid.

- Accurate and Reliable Results: the analyzer provides consistent and reliable readings, essential for effective transformer maintenance and decision-making.

In essence, a blend of rapid testing, user-friendliness, cost-effectiveness, and accuracy intrinsic to the TOR-2 hydrogen analyzer make it all important for transformer oil testing in India. Its adoption can improve operational efficiency, reduce downtime, and extend the service life of transformers across the country.

The adoption of TOR-2 hydrogen analyzer can considerably contribute to the reliability and stability of India’s power grid. As the country continues to grow and further upgrades its electrical infrastructure, the instruments like the TOR-2 will play a vital role in ensuring that this growth is supported by robust and reliable transformer maintenance practices.

Hydrogen and Moisture ...

Hydrogen and Moisture ...