Tan delta test for transformer oil in India is more than a mere procedural task; it’s a cornerstone for ensuring the optimal functioning and longevity of this country’s power sector. This kind of assessment brings an in-depth evaluation of transformer oil condition, which is key to the operation of power engineering equipment. The significance of this test stems from its ability to detect subtle changes in the primary properties of oil, which may be indicative of underlying issues. Higher tan delta points often indicate an increase in dielectric loss, suggesting the potential deterioration or contamination of oil. On the other hand, lower tan delta points are generally indicative of strong insulating properties, which represent better oil conditions.

In India’s diverse climatic conditions, the relevance of tan delta test takes on added significance. The diverse environmental landscape of this country may dramatically influence the oil performance and effectiveness. The factors, such as temperature fluctuations, humidity levels, and regional atmospheric conditions, can all impact the oil effectiveness. Regular measurements run by operators as part of tan delta test evaluate how these environmental variables affect the insulating capabilities and overall condition of oil, ensuring the efficient and safe operation of transformers across India.

Importance of tan delta test for transformer oil

The application of tan delta test in India’s intricate power infrastructure is a strategic move toward improved maintenance and operational excellence of the power engineering equipment. This test extends beyond superficial inspections and provides profound insight into the condition of transformer oil. It identifies critical markers of deterioration, such as oxidation, water or solids content. If left unchecked, these factors may considerably diminish the insulating performance of oil, compromising the operational reliability and safety of transformers.

More frequent tan delta testing is pivotal for a proactive maintenance schedule. Timely identification of issues through this test enables timely remedial actions, preventing the costly failures and extending the service life of transformers. This proactive approach is particularly crucial in the densely populated urban centers and critical industrial zones of India. In these areas, the ramifications of transformer failures are far-reaching, potentially leading to widespread power outages and elevated safety risks. Therefore, tan delta test emerges as an essential tool in safeguarding against these challenges, contributing to the stability and reliability of India’s power grid.

Importance of tan delta test considering the climatic diversity of India

Tan delta test for transformer oil is necessitated by the climatic diversity of India. The wide range of environmental conditions across the country, from humid tropics to arid deserts, may considerably affect the properties of mineral oils. These variations in climate have a direct impact on the ability of oil to insulate and protect the transformer core and windings.

In regions with high humidity and temperature, mineral oil is more susceptible to moisture absorption and thermal degradation. Conversely, in colder climates, the viscosity of oil may increase, potentially reducing its insulating performance. Tan delta test is thus vital for assessing the adaptability and resilience of transformer oil under such varied environmental stresses. Conducting this test on a regular basis, the operators can ensure that the transformer oil maintains its optimal parameters, thereby enhancing the overall performance and longevity of transformers across the dynamic landscape of India.

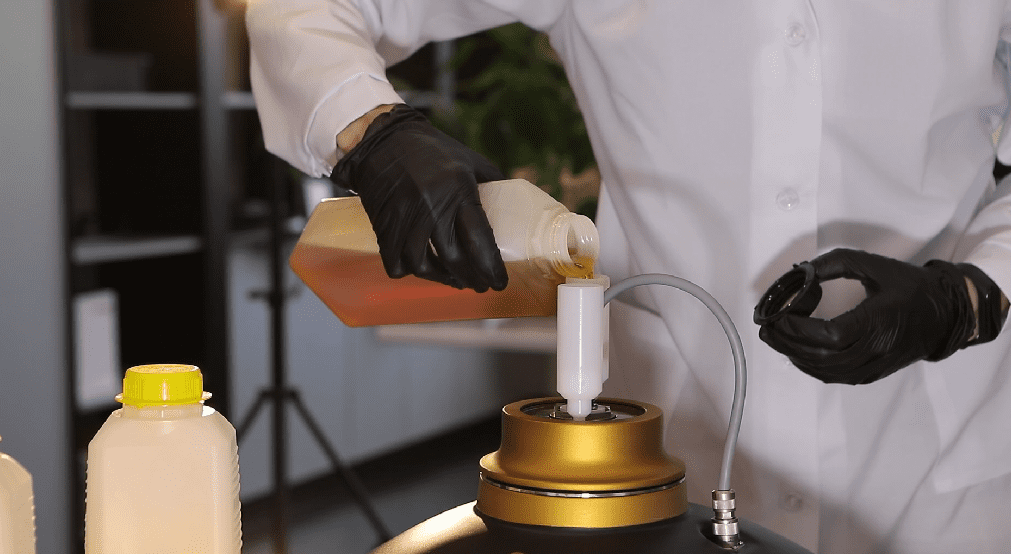

Tan delta test with the use of TOR-3 device in India’s power sector

With regard to power distribution and maintenance within India, a TOR-3 device has been introduced in this field as a pivotal instrument to conduct the tan delta test for transformer oil. The increasing adoption of the TOR-3 attests the growing recognition of its importance for maintaining the efficiency and reliability of transformers throughout India’s extensive power networks. The TOR-3 tester designed in compliance with the stringent IEC 60247 standards offers a sophisticated, fully automated procedure for accurate measurement of dielectric loss tangent, permittivity, and other critical properties of transformer oil.

The operation principle of the TOR-3 is based on applying a test sinusoidal voltage to both a reference capacitor and an oil sample in the device’s measuring cell. The voltage can reach an effective value of up to 2 kV, allowing for comprehensive analysis of oil properties. During the tan delta test, the TOR-3 carefully examines the differences in signal amplitudes and phases between the reference capacitor and the oil sample. These differences reveal insights into the dielectric constant of oil, providing valuable data about the dielectric permittivity of this liquid. In addition, the phase difference indicates the dielectric loss tangent of oil, a key measure for evaluating the transformer oil quality. This accurate signal analysis method enables the TOR-3 to offer detailed diagnostic evaluation of oil, effectively assessing its insulating capabilities and overall suitability for use in transformers.

Advantages of TOR-3 system for tan delta testing

Tan delta test for transformer oil with the use of TOR-3 provides critical insights into oil properties that enhance transformer maintenance:

- Speed and Accuracy: the TOR-3 excels in delivering rapid measurements with consistently high accuracy; this combination is essential for prompt decision-making in transformer maintenance, which allows operators to effectively respond to varying conditions.

- Automated Process: measurements with the use of TOR-3 are fully automated and computer-controlled. This automation streamlines the testing process, as well as reduces the likelihood of human errors, ensuring consistent results across multiple tests.

- Data Management: equipped with the innovative Tangent Service engineering software, the TOR-3 significantly enhances data management capabilities. This feature enables real-time viewing of test results and maintains an archive of measurements in both graphical and digital formats, facilitating the comprehensive data analysis.

GlobeCore’s impact on tan delta test for transformer oil in India

GlobeCore has played a significant part in promoting the transformer oil tests across India through its comprehensive range of testing equipment designed for detailed analysis of transformer oil. The TOR-3 tester is essential for measurement of key parameters, such as tan delta, resistivity, and dielectric permittivity. Such devices represent a notable advancement within the context of India’s power sector.

GlobeCore‘s range of testing equipment is particularly well-suited for laboratory settings, enabling technical professionals to conduct accurate evaluations of transformer oil purity and quality. It really matters whether the dielectric liquid is newly produced or has been regenerated. Such testing accuracy guarantees that the dielectric oils used across India’s vast power grid comply with stringent quality standards, thereby enhancing the overall safety and performance of the power infrastructure.

Oil Tan Delta ...

Oil Tan Delta ...